Rotary Resin Shutoff Valve-III

For GAS ASSIST applications

Our Rotary Valve provides UNPRECEDENTED RELIABILITY and FLEXIBILITY!

It provides many cycles of service with the flexibility to use a wide range of resins, pressures and temperatures

- Withstands temperatures of 800°F continuously.

- Use with any pressure and resin with or without fillers

- Use on molding machines 375 ton or larger

- No adapters required

- Hydraulically operated

- Simple maintenance

- Easily re-built

- Standard thread 1 ¾” male & female

- 1/2" or 3/4" through hole with no restrictions

- Tip openings, angles, threads and special sizes may be customized to fit your machine.

Description:

The JDL Rotary Resin Shut Off Valve installs easily between the injection barrel and nozzle. The standard model has a 1-3/4"-8 male threaded end to engage in the barrel and a 1-3/4"-8 female thread on the opposite end to accept the nozzle. Minimum swing clearance of 12" is required.

Its unique push-push design results in 86.9 foot-lbs. torque at pressure. The latest technology in high temperature seals is used for top performance over the life of the valve and to prevent oil leakage. The manifold has an internal oil flow design and does not require external piping. It has one inlet port and one outlet port. The body is heat-isolated by using free air between it and the manifold plates.

Seal kits and parts are available as "off the shelf" items with complete instructions and installation tools.

Requirements:

- Hydraulic power unit capable of providing 2 GPM flow and set at 500 PSI max.

- Hydraulic hoses rated at 1000 PSI with fittings for 1/4-18 NPT ports.

- Hydraulic 4-way spring return solenoid-operated control valve.

- Four heater rods 3/8” dia x 6” long

Installation:

Connect the pressurized hose from the hydraulic power unit’s open position port to the control valve’s open position port. Install the heater rods and nozzle. Screw the Rotary Resin Shut Off Valve into the barrel. Connect two hoses from the 4-way solenoid control valve to the respective “OPEN” and “CLOSE” ports on the Rotary Resin Shut Off Valve. Wire the control valve’s solenoid. Attach and wire the thermocouple and heater rods.

Heat these zones until the temperature required is stabilized.

Operate the valve until air bleeding is complete.

Test for hydraulic leaks. If satisfactory, proceed with injection and processing.

OPERATION for GAS ASSIST:

The TIMING of the Rotary Resin Shut Off Valve and INJECTION of the resin MUST BE SYNCHRONIZED using the following procedure.

- COMPLETE RESIN INJECTION

- CLOSE VALVE

- INJECT GAS

THE ROTARY VALVE III SHOULD NOT BE USED WITH CONVENTIONAL MOLDING.

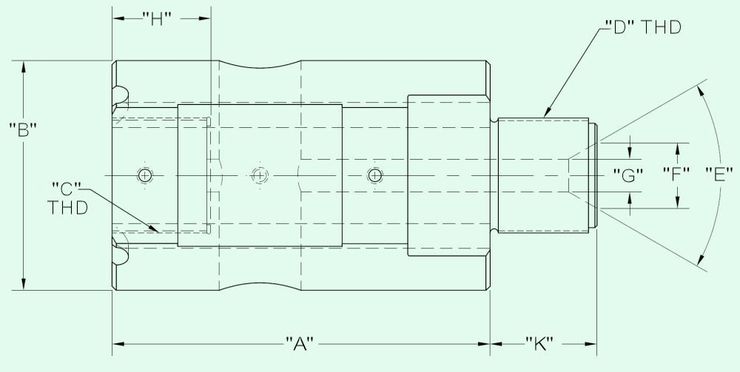

| Standard and Custom Specifications | A | B | C (THD) | D (THD) | E | F | G | H | K |

|---|---|---|---|---|---|---|---|---|---|

| Standard | 6.00" | ø3.5" | 1-3/4"-8 | 1-3/4"-8 | 60º | ø1.00" | ø.50" | 1.44 | 1.62" |

| Custom Specifications (Fill in Blanks) |

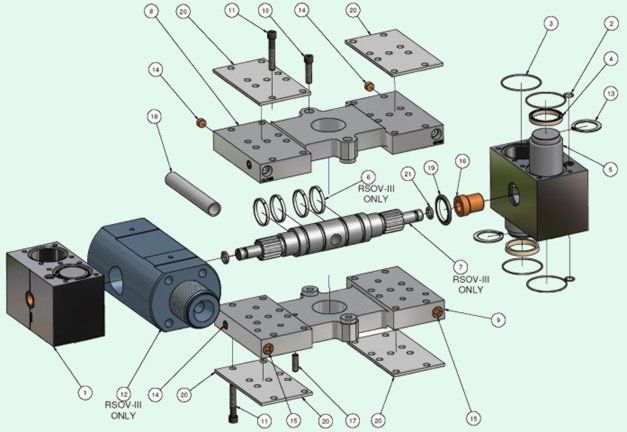

| Parts List | |||

|---|---|---|---|

| ITEM | PART NO. | DESCRIPTION | QTY |

| 1 | rsov-det01 | Cylinder Block | 2 |

| 2 | rsov-det02 | Seal-Manifold | 4 |

| 3 | rsov-det03 | Seal-Cyl Block | 8 |

| 4 | rsov-det04 | Seal-Piston (U-Cup) | 8 |

| 5 | rsov-det05 | Piston | 4 |

| 6 | rsov-det07 | Seal-Pinion | 4 |

| 7 | rsov-det08 | Pinion | 1 |

| 8 | rsov-det09U | Upper Manifold | 1 |

| 9 | rsov-det09L | Lower Manifold | 1 |

| 10 | rsov-det13 | 1/4-20 x 1 SHCS | 4 |

| 11 | rsov-det14 | 1/4-20 x 1-1/2 SHCS | 36 |

| 12 | rsov-det16 | Nozzle Body | 1 |

| 13 | rsov-det18 | Spring Retaining Ring | 8 |

| 14 | Plug 1/8 NPT | Plug 1/8 NPT | 8 |

| 15 | Plug 1/4 NPT | Plug 1/4 NPT | 2 |

| 16 | rsov-det23 | Bushing | 2 |

| 17 | rsov-det25 | 1/4-20 Flat Pt Set Scr | 1 |

| 18 | rsov-det26 | Conduit | 1 |

| 19 | rsov-det29 | Seal-Housing | 2 |

| 20 | rsov-det35 | Manifold Washer | 4 |

| 21 | rsov-det36 | Quad Ring | 2 |

Navigation

Contact